What is the 2K Grind & Seal

The ONYX 2K GS (Grind & Seal) is a superior concrete coating system incorporating our 2K CRU WB: a two-component, chemically resistant, water-based polyurethane that surpasses traditional single-component sealers. This unique chemistry sets a new standard for protection and aesthetics in concrete finishes.

Who the 2KGS is for

The system is used in a wide range of facilities: entertainment venues, food courts, warehouses, manufacturing, animal care, hospitals, schools, retail, offices, garages and more.

Why the 2KGS

- Nonporous, monolithic, seamless surface resists chemical and fluid penetration

- Easy-to-clean surface requires minimal maintenance

- Stunning appearance available in both gloss and matte finishes

- Slip-resistant when appropriate aggregate is added

- Breathable sealer helps tolerate moisture and vapor problems

- Yellowing-resistant due to polyurethane chemistry

- V.O.C. compliant

- Manufactured in compliance with SCAQMD (South Coast Air Quality Management District) standards

- Easy application process reduces the possibility of error

Gloss and Matte Options

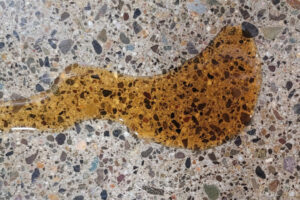

The 2K GS offers versatility with either a gloss or matte finish. The gloss attracts those desiring a shiny, showroom-like surface, while the matte provides a subtle appearance, breathing life into the concrete.

Glossy Finish

Matte Finish

Shade of Concrete

Lighten the gloss finish by substituting the initial pour with ONYX Epoxy WB Fast.

Light Gloss Finish

Dark Gloss Finish

Fast Cure Primer

ONYX Epoxy WB Fast has a 2 hour cure time and will speed up the application process by allowing both coats to be installed on the same day.

Increased Safety

To achieve a slip-resistant finish, lightly broadcast aluminum oxide (80-120 grit) into the system and then backroll. It is always best to provide a mock-up sample to determine the needs of the coefficient of friction as outlined by ANSI A137.1. Ensure the size of the aggregate and the amount used do not make the floor too difficult to clean and maintain.

Resist Stains & Improve Cleanup

A primary feature of the 2K GS is how easy it is to clean and maintain the floors from basic usage. The nonporous surface offers excellent resistance to stains caused by numerous liquids and chemicals.

Mixing

The mix ratio of the 2K CRU WB is 3 to 1 by volume. That is, 3 parts of A (resin) to 1 part of B (isocyanate). Mix Part A and Part B together at medium speed for 2 minutes under mechanical agitation with a jiffy mixer.

Pour Part A into a mixing bucket. Add Part B (in the correct 3:1 ratio) and mix for 2 minutes until uniform, scraping the sides to ensure a uniform mix. Always use clean mixing buckets to prevent contamination of the product.

As with all water-based polymers, any mixed resin left in the bucket may take several days to harden with the lid off. The 2K CRU WB has a very long pot life. The mixed product will remain in liquid form for many hours with exposure to air before slowly turning into a gel form. Leftover mixed material should be rolled out onto a substrate such as cardboard in multiple coats to thoroughly harden for proper disposal.

Application Process

Apply the first coat of the 2K CRU WB at 350-400 sq ft/gal. Using a 3/8″ non- shedding roller cover, quickly roll out the floor. Immediately after, cross-roll the coating in the opposite direction to avoid roller marks. (When applying a gloss system, substitute the primer with Epoxy WB Fast to lighten the finish and speed up the cure time between coats.) Apply the second coat of the 2K CRU WB at 400 sq ft/gal following the same steps as the first coat. (To achieve a slip-resistant finish, lightly broadcast aluminum oxide (80-120 grit) into the system and then back roll.) Always provide a mockup to ensure finished product is reflective to job expectations.