Forged in the industrial world, ONYX Concrete Coatings create floors that stand up to heavy forklift traffic, industrial processing equipment, and employee wear. Facility/maintenance managers, plant engineers, and everyday employees will be more comfortable, productive, and safe with ONYX under their feet.

There are unique conditions between a food processing facility, an aerospace factory, a pharmaceutical plant, and a paper mill. Whether chemicals attack the concrete, or the surfaces require resistance to slips and falls—ONYX has the solution.

Industries

- Aerospace

- Automotive

- Cannabis

- Chemicals

- Cosmetics

- Food / Beverage

- General Manufacturing

- Machine Shops

- Pharmaceutical

- Pulp/Paper

- Textiles

Industrial manufacturing facilities are not limited to these product lines. Under the COMMERCIAL LINE, thin mil floors can be used in foot traffic areas. Under the DECORATIVE LINE, the Hybrid, Quartz, and Chip Systems may provide thickness/durability. Where natural concrete is desired, the RESURFACING LINE includes the 2K Grind & Seal System, which is a cost-effective, aesthetically satisfying, nonporous, and high performing solution. Concrete polishing is also an option.

Novolac System

When acids and harsh chemicals become so aggressive that urethane concrete and high build epoxies cannot hold up, turn to the chemical/acid-resistant Novolac System. Refer to the CHEMICAL RESISTANCE CHART taking into account the particular chemicals/acids, their concentrations, and whether it is for splash/spill or continuous exposure. (These products are not meant for continuous immersion without a flexible, waterproof membrane underneath.) The system has a dull finish. It should be installed as a resin rich, nonporous, broadcast floor rather than a dry mix, trowel down.

Recommended Areas for usage:

- Chemical Processing

- Chemical Storage

- Secondary Containment

- Battery Charging

- Plating Lines

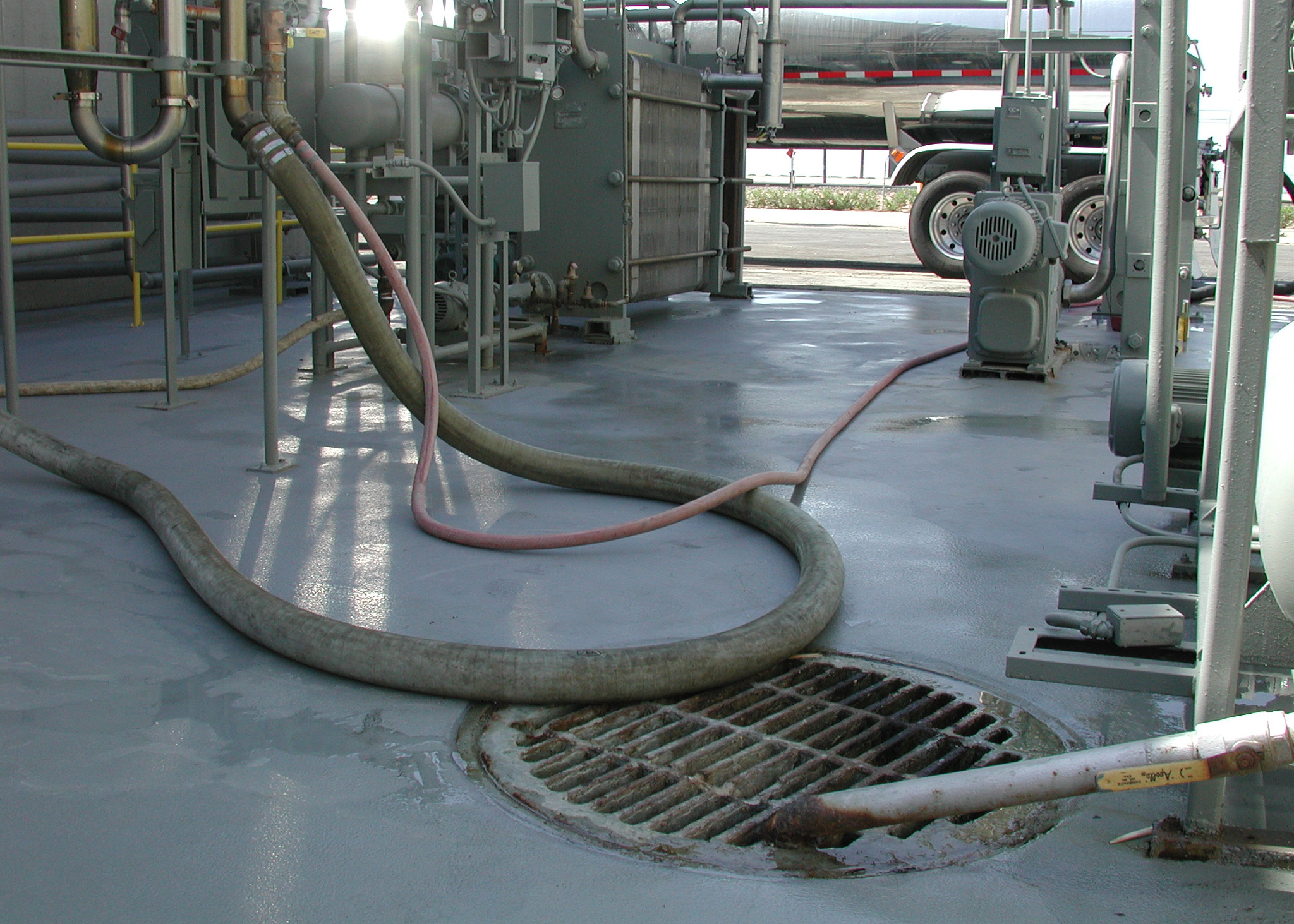

- Optional Title Here Optional caption here

- Novolac at work caption here

Grouting System

Whether you need grout material for sloping, building a berm, or packing in large voids, EPOXY GROUT and EPOXY GROUT FAST provide a cost-effective solution, without compromising strength or durability. If the grout material is too dry, the EPOXY BLOCK FILL can be used as a scratch coat to encapsulate surfaces such as a cinder block wall or damaged concrete. All grouting systems require a primer and should be sealed with a grout coat to fill in the pores from a dry mix. If desired, another system can then be installed over the grout.

ONYX Crete (Urethane Concrete) System

ONYX Crete is the ideal system for wet concrete in an abusive environment. Epoxy floors are great for most applications, but are more susceptible to failure in wet manufacturing areas (particularly food plants) and commercial kitchens. Epoxy is rigid and doesn’t respond well to thermal shock. Once water finds a hairline crack, it penetrates and spreads. however, ONYX Crete is engineered to withstand nasty, hot temperatures, often occurring due to thermal shock / cycling.

Recommended Areas for usage:

- Restaurant

- Dairies

- Bakeries

- Meat / Poultry

- Kitchens

- Breweries / Wineries

- Wash Down

- Water / Wastewater

- Coolers / Freezers

- Ovens / Fry Lines

- Kettle Rooms

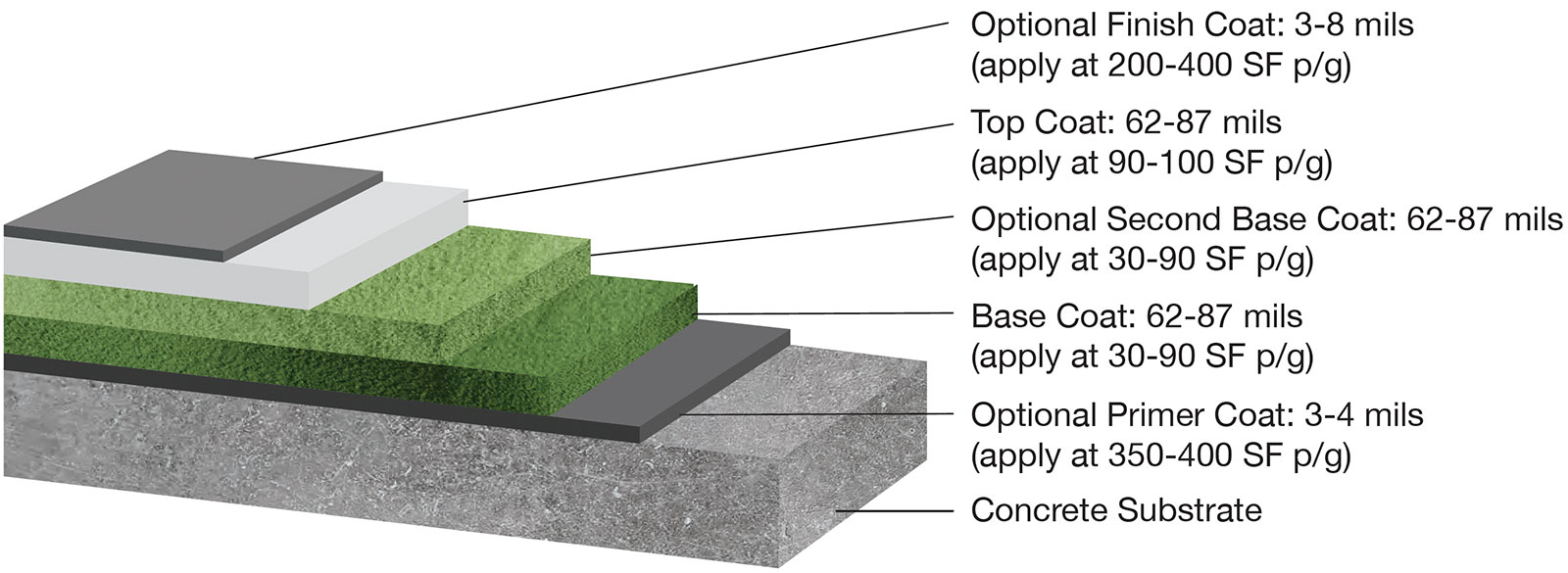

ONYX Crete System

This three component system consists of a base coat(s) (ONYX CRETE SL) and a top coat (ONYX CRETE TC), ranging from 1/8″ – 3/8″. If going thicker than 3/16″, apply two base coats.

It is often installed with an integral cove base.

ONYX Crete Color Chart

- Blue

- Green

- Tile Red

- Sand Beige

- Expresso

- Dark Grey

- Medium Grey

ONYX Crete is also available as a decorative system. Refer to the Hybrid System in the Decorative Line. Color selection is only to be used for color approximation. Onsite mockups provide the most accurate results. Colors may come in gloss or matte finish contingent upon the urethane sealer final coat.

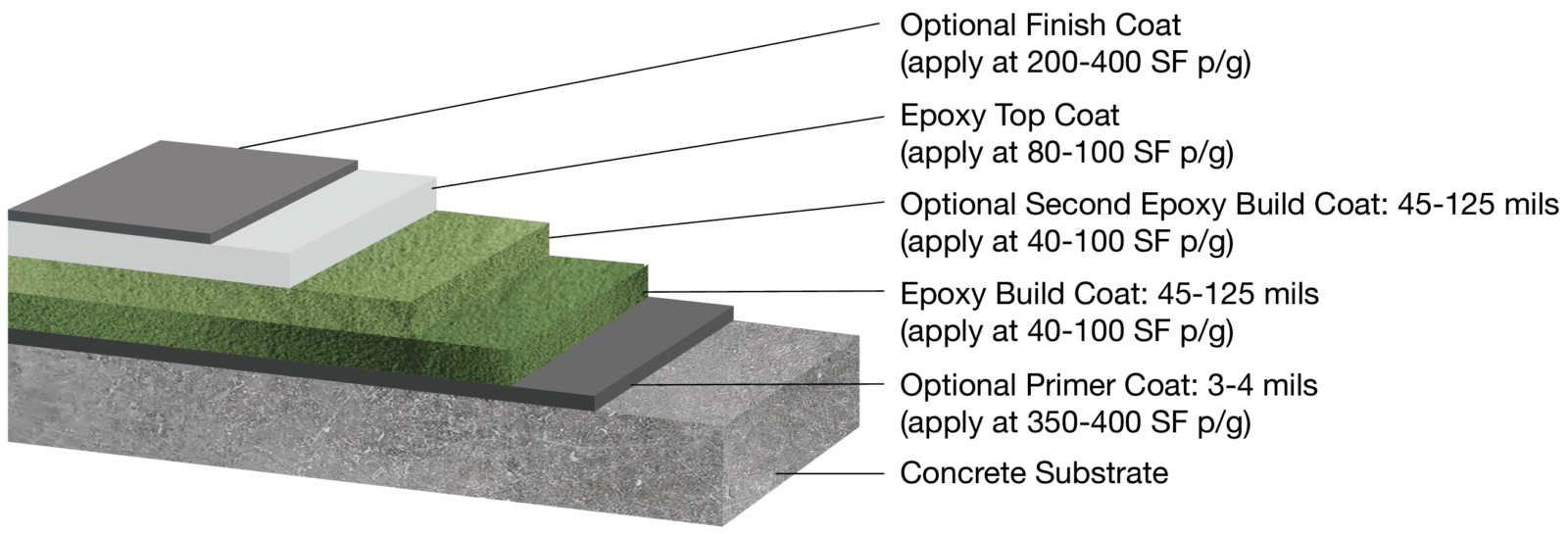

Epoxy Build Systems

Heavy duty epoxy is the industry standard for (dry) manufacturing facilities. EPOXY BUILD COAT and EPOXY TOP COAT are 100% solid, industrial strength epoxies that are mixed with aggregate to create a more durable, slip-resistant floor. They are available in fast cure versions (EPOXY BUILD COAT FAST and EPOXY TOP COAT FAST) when a quick turnaround time is required.

Recommended Areas for usage:

- Aerospace

- Pharmaceutical

- Electronics

- Automotive / Service

- Aisle Ways

- Paper Mills

- Textiles

- Fasteners

- Power / Energy

- Recycling

- Printing

- Restrooms

- Warehousing

Broadcast System

Epoxy Build Systems can be installed as a broadcast system (i.e., tossing aggregate into the coating surface while wet), requiring a base coat(s) and top coat. Unlike the Trowel Down Mortar System, this is resin-rich, nonporous coating.

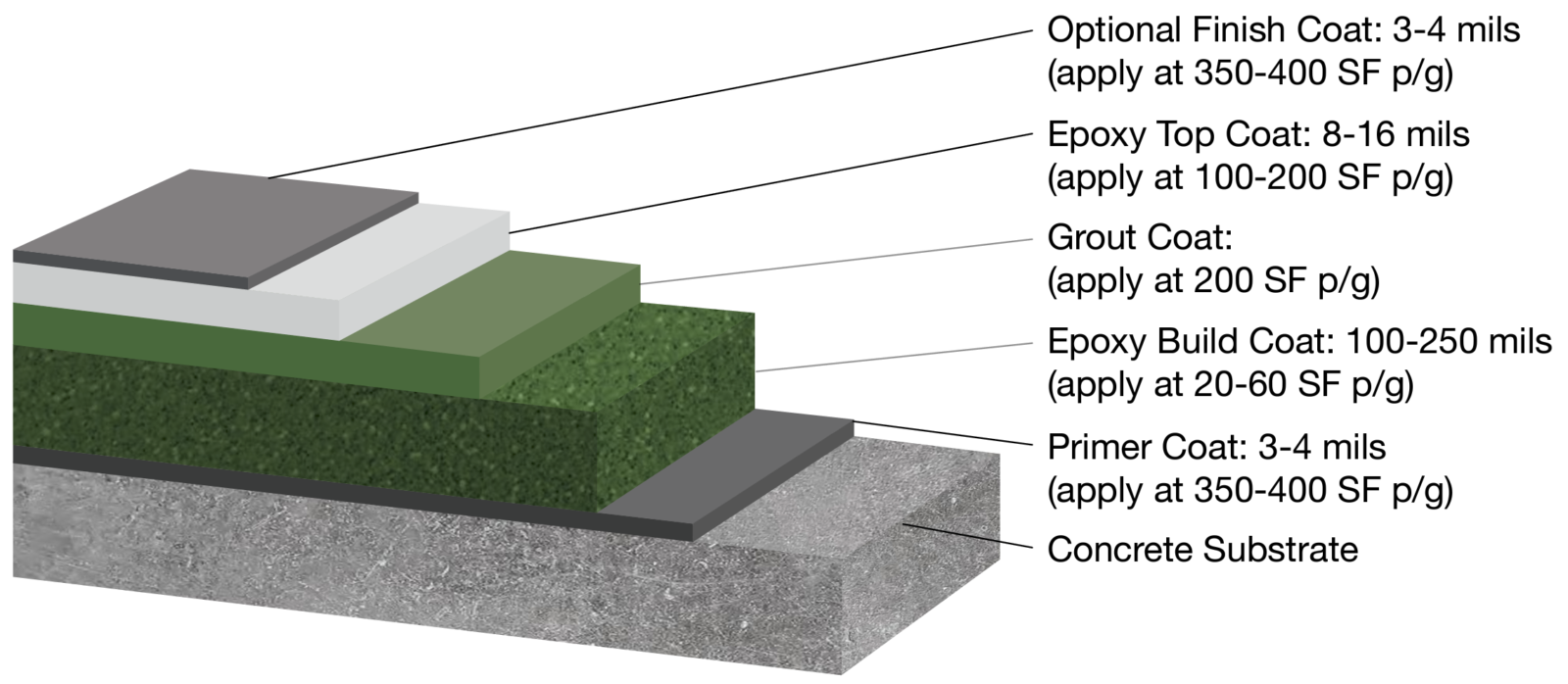

Trowel Down Mortar System

Epoxy Build Systems can also be installed as a Trowel Down Mortar System (i.e., mixing the aggregate into the resin prior to installing on the floor). The dry mix optimizes durability through additional thickness. The system is porous and should only be used in dry environments. It requires both a primer and grout coat, in addition to the top coat.

- Black

- White

- Tile Red

- Safety Red

- Night Grey

- Dark Grey

- Medium Grey

- Light Grey

- Dark Beige

- Sand Beige

- Light Beige

- Dark Blue

- Pastel Blue

- Dark Green

- Safety Yellow

To enhance the appearance, apply a finish coat of 2K CRU WB in either Gloss or Matte.

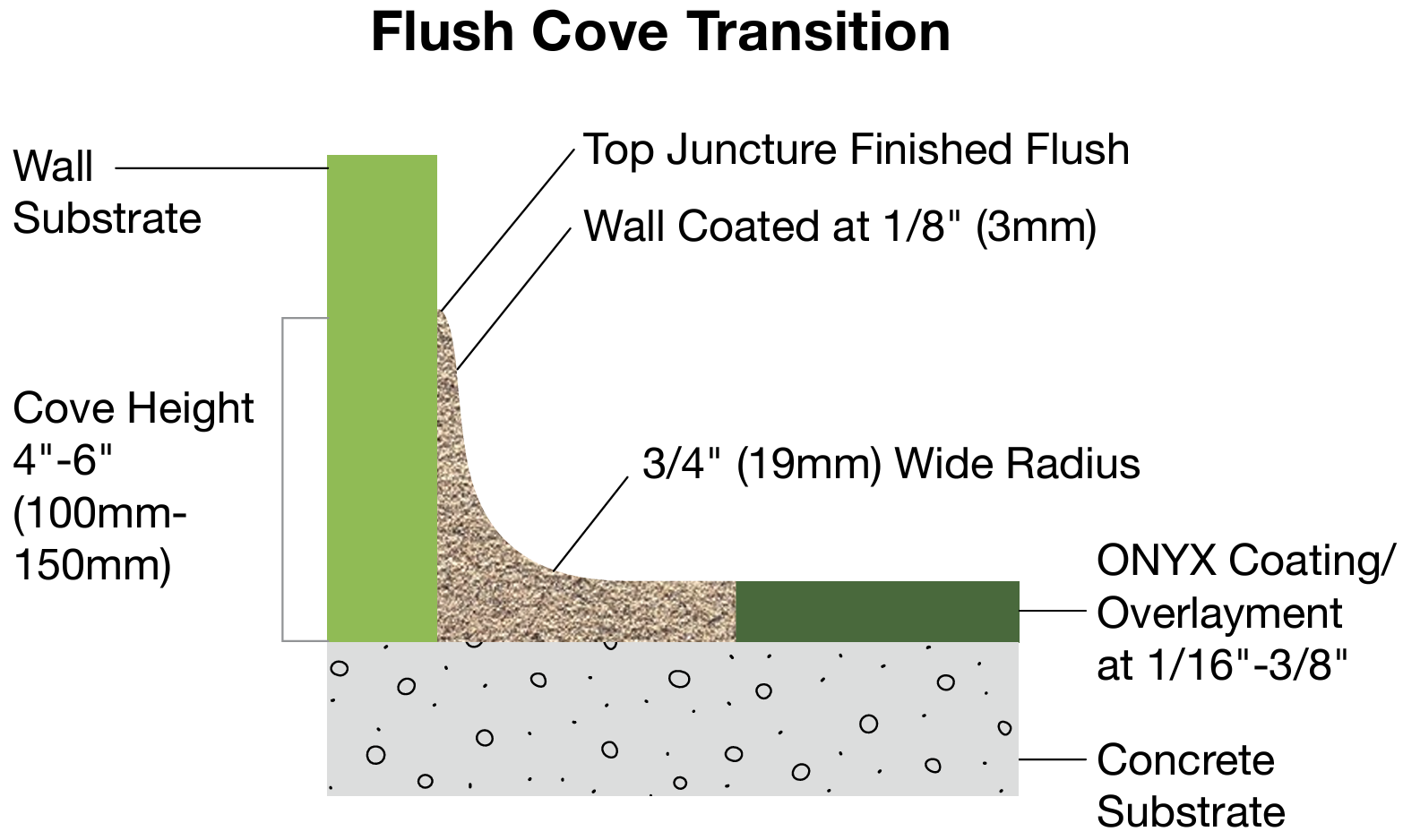

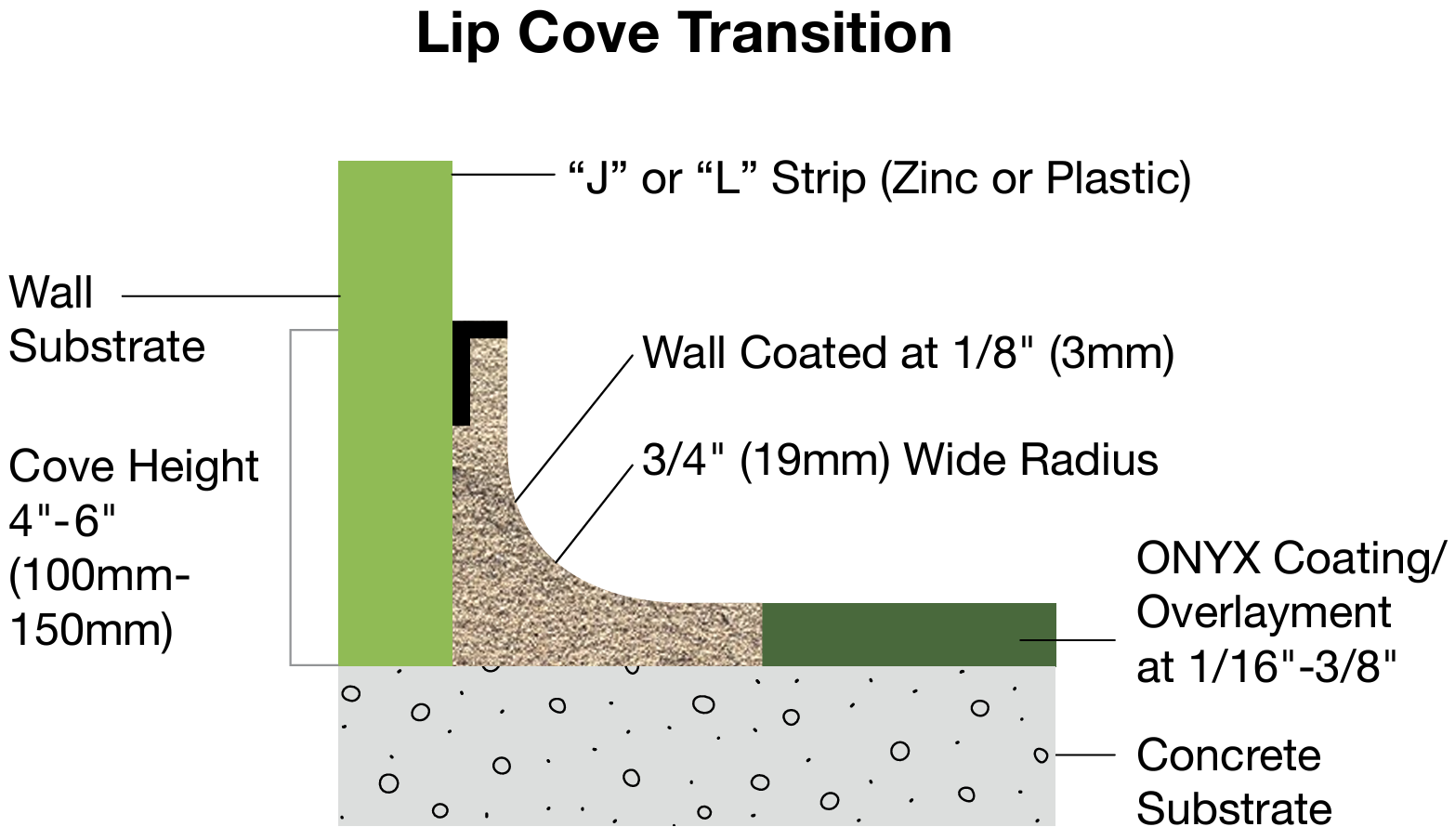

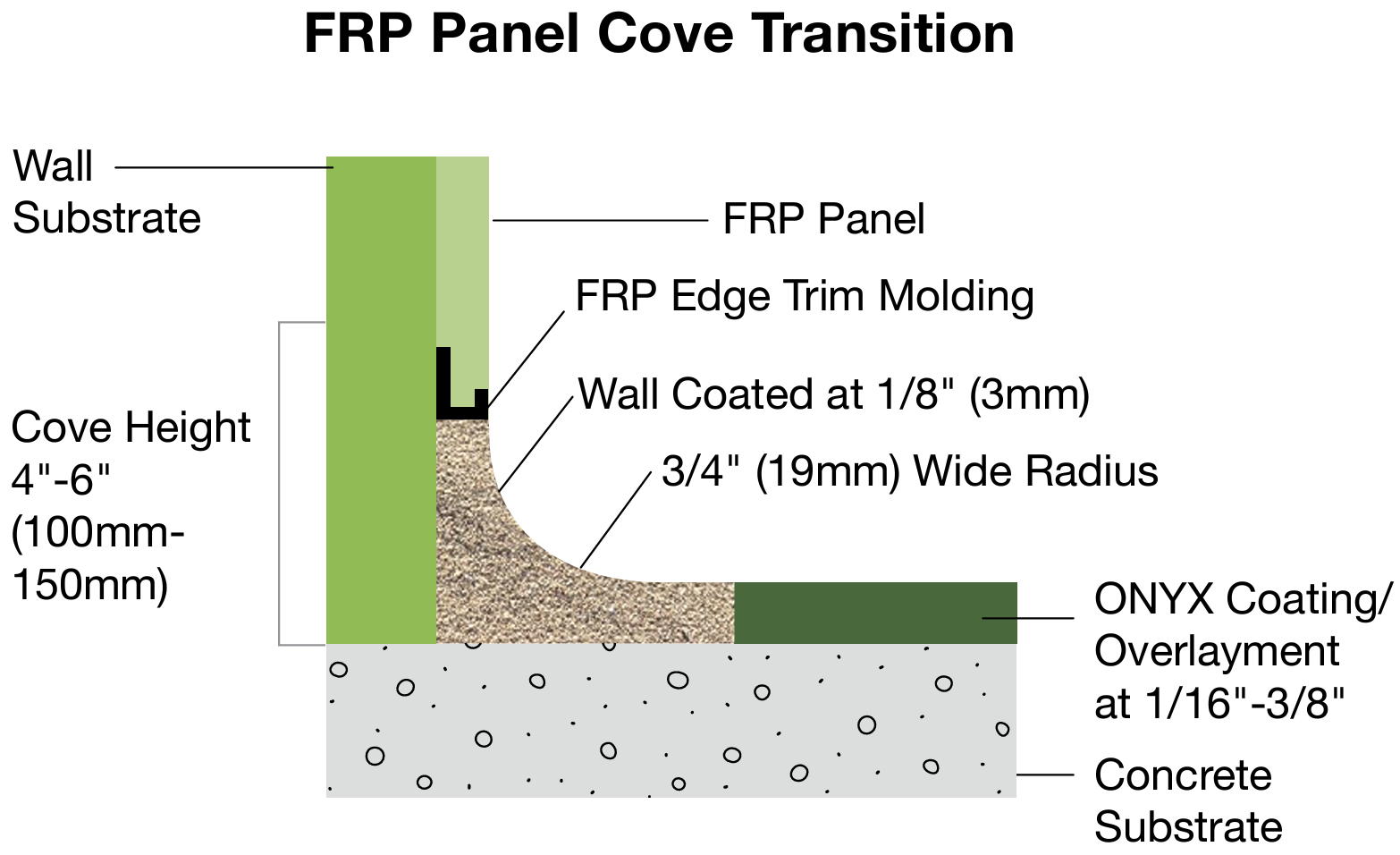

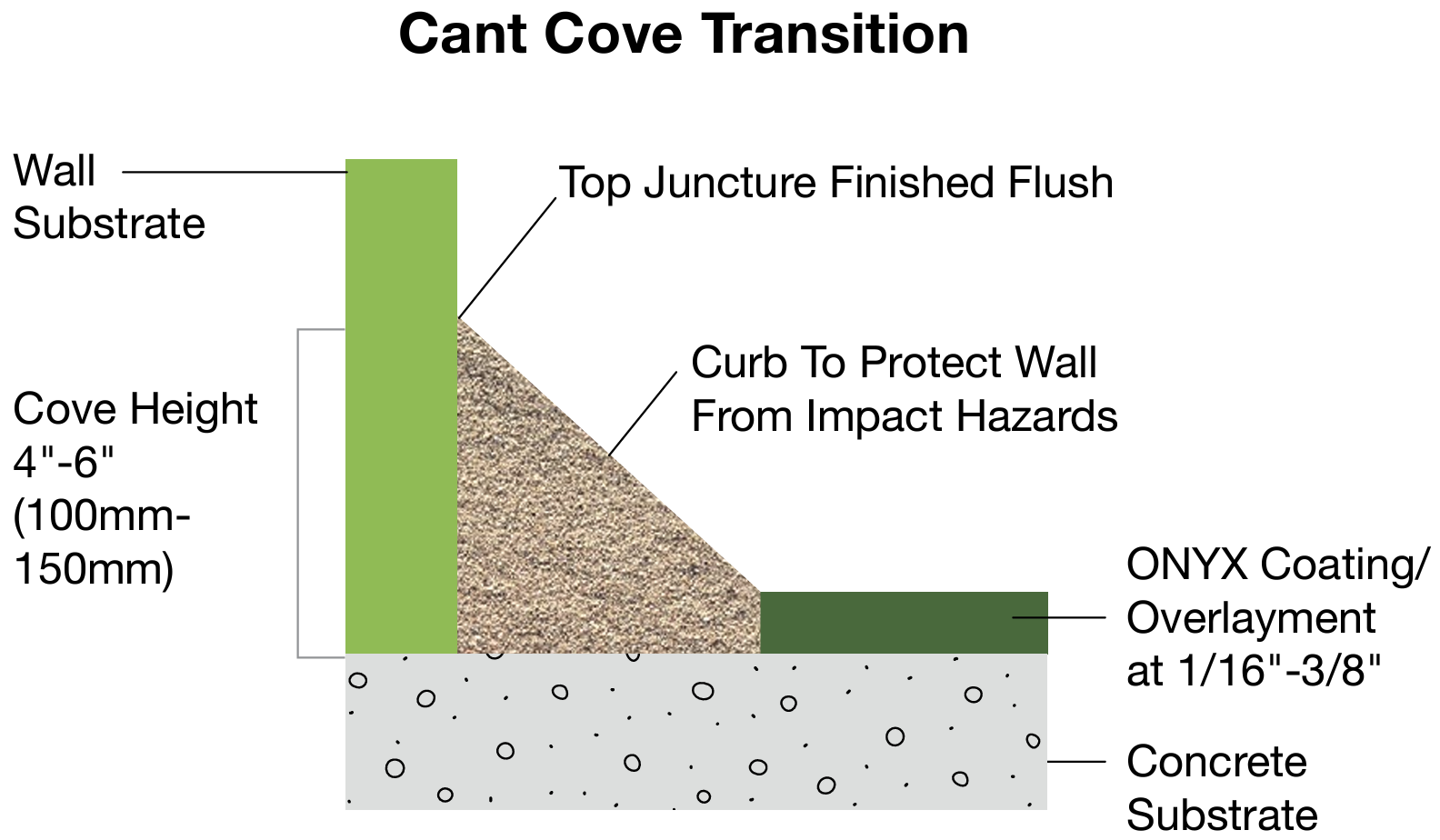

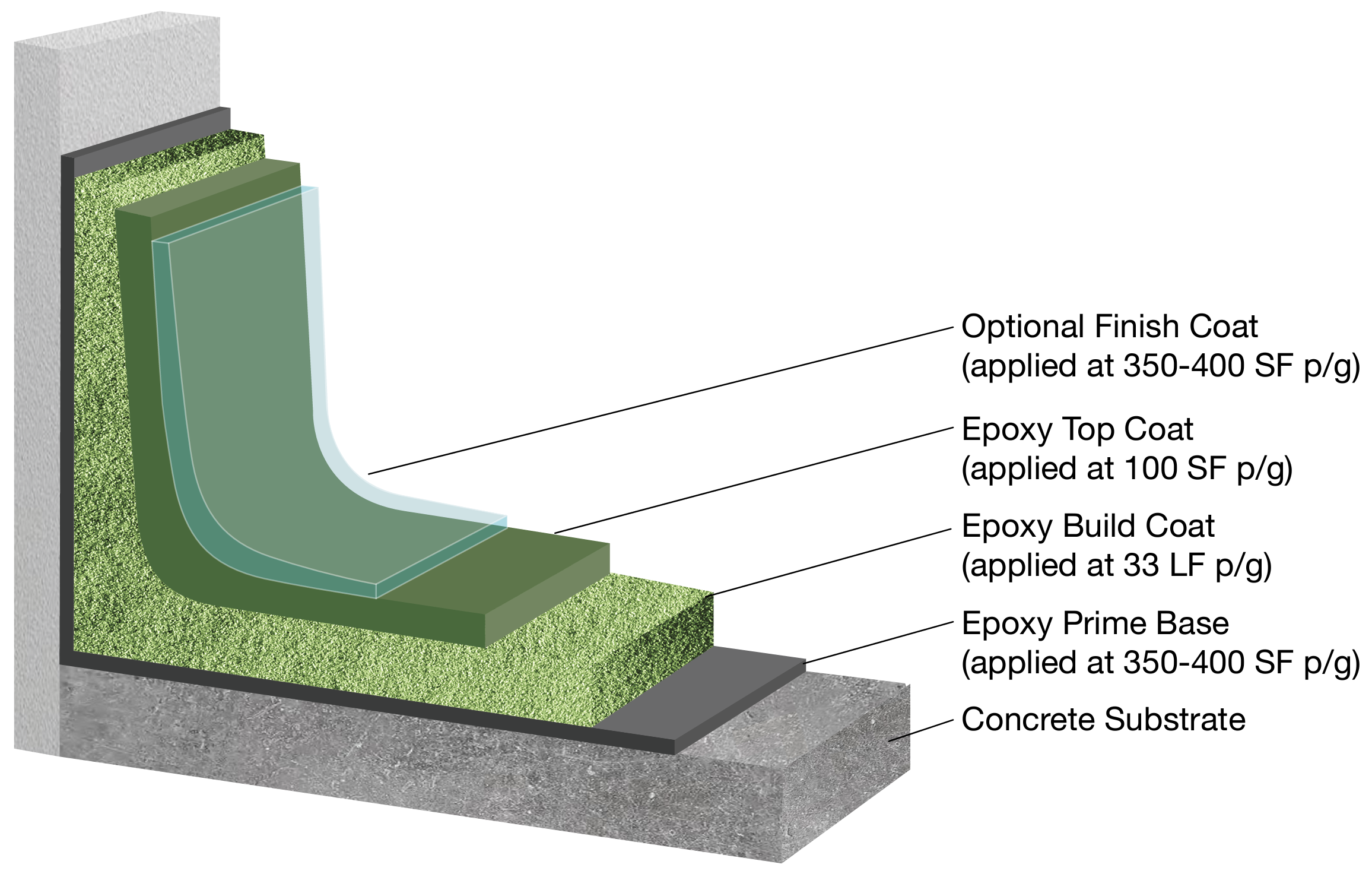

Cove Base System

ONYX epoxy and urethane concrete floors are often installed along with a vertical cove base, forming a non-porous floor that creates a pan-effect. It is ideal to contain water, chemicals, and other fluids from penetrating where the floor and wall meet. The Cove Base is also ideal in any sanitary environment that desires easier cleaning and maintenance. EPOXY BUILD COAT is recommended for solid pigmented systems, and EPOXY HIGH CLEAR is recommended for Quartz and Hybrid Systems. Though they are typically installed at 4-6″, they are sometimes installed much higher.

The Cove Base System can be installed using multiple methods, particularly at the termination point on the vertical surface. The cove base can be installed using a “J” or “L” strip (recommended) or flush against the wall. It can also be installed under FRP or as a cant in a heavy industrial environment. Refer to the details below for further information.

Recommended Areas for usage:

- Kitchens

- Food Processing

- Chemical Processing

- Wash Down

- Chemical Containment

- Wet Environments

- Laboratories

- Clean Rooms

Cove Base Details