Concrete has many reasons for resurfacing. Regardless if it is old concrete in need of extensive patching/repair, or a freshly poured slab that needs to be sealed or polished, ONYX has solutions.

Polish System

Polishing concrete has become popular over the years. Whether a 100 level or 3,000 level system, ONYX offers both the LITHIUM DENSIFIER and the LITHIUM GUARD sealer. Unlike epoxy/urethane coatings, concrete polishing is not a nonporous surface, but will certainly seal the concrete, creating a sharper look.

Joint Fill System

The polyurea JOINT FILLER is strong enough to endure abuse, while flexible enough to handle movement. Honoring the joints will help prevent future cracking from occurring throughout the slab.

Available in Six Colors

- White

- Medium Grey

- Expresso

- Tile Red

- Black

- Safety Yellow

Scrub/Seal System

ONYX GUARD is a single component, lithium-based sealer applied after mechanically scrubbing the concrete. Apply multiple coats avnd burnish with 800 and/or 1500 grit pads to harden the sealer for a better sheen and lifespan.

Patch Systems

ONYX carries multiple concrete patch options to fill cracks, spalls, and divots. Often these patches are covered up with a pigmented coating or a clear sealer. Sometimes they are left alone.

Polymer Patch

Polymer Patch is a two-component polyurea. It is often used for its user friendliness. It works especially well for concrete polishing involving vehicle traffic too heavy for a cementitious product. Its low viscosity allows the resin to sink deep into the cracks.

Available in Six Colors

- White

- Medium Grey

- Expresso

- Tile Red

- Black

- Safety Yellow

Epoxy Patch

ONYX epoxies are great for coating over with another system. For smaller cracks, holes, and divots, use EPOXY PATCH KIT mixing in fumed silica to create a paste texture. For larger spalling or deteriorated concrete, mix aggregate with EPOXY GROUT, EPOXY GROUT FAST, or EPOXY BLOCK FILL (see Grouting Systems, page 9). ONYX recommends grinding the patches flush once they’re cured.

Cementitious Patch

ONYX carries a fast cure cementitious patch product to be used as a feather finish. This can be a cost-effective solution on a number of projects. It provides the look of natural concrete and cures quickly.

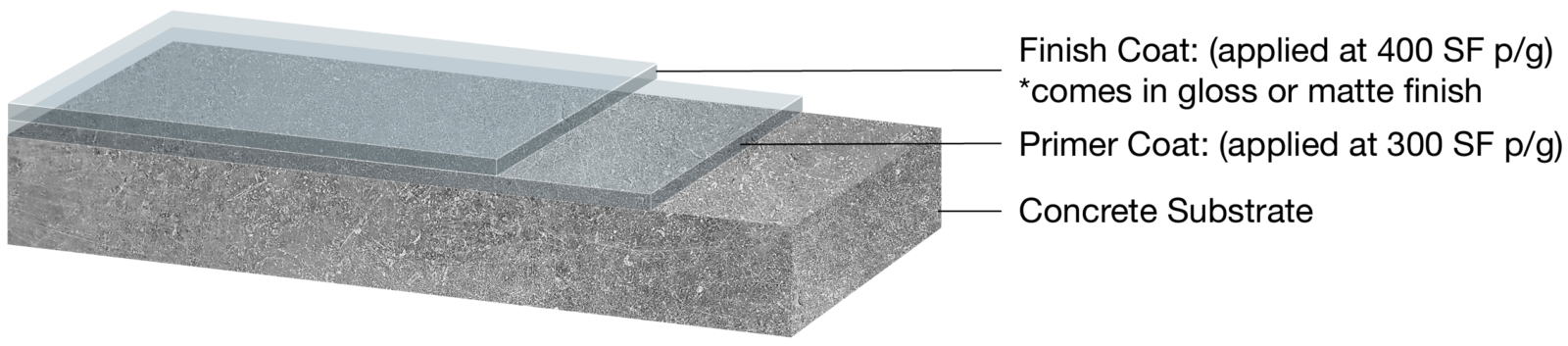

2K Grind & Seal System

The ONYX 2K Grind & Seal System is one of the best value-based systems on the market. It provides a cost-effective way to enhance the appearance of exposed concrete with a nonporous sealer. Once the concrete has been ground to a 30/40 level and patched, apply the 2K CRU WB waterbased urethane as the primer. If using EPOXY PRIME BASE or EPOXY PRIME BASE FAST, add UV inhibitors. Do not expose the epoxy to direct sunlight. Do not use PRIME BASE FAST PLUS.) After applying the primer, apply the 2K CRU WB as the top coat. The product comes in either a Gloss or Matte finish, providing the end user with aesthetic options. A fine aggregate such as aluminum oxide (80-120 grit) can also be used to achieve a slip-resistant finish. It is recommended to always do an onsite mockup of this product prior to the start of the project. Since the system is clear, the finished appearance will vary slab to slab. Note: if applying over a cementitious topping/overlayment, use the EPOXY PRIME BASE or EPOXY PRIME BASE FAST as your primer.

Benefits

The 2K Grind & Seal yields some benefits over concrete polishing or traditional scrub and seals.

- Nonporous protection

- Nonporous ease of cleaning

- Option for slip-resistant aggregate

- Less labor/logistics than polishing

- Better stain resistance

Recommended Areas for usage:

- Entertainment (arenas, stadiums, theatres)

- Restaurant Dining Areas / Lobbies

- Warehouses / Distribution

- Manufacturing Plants

- Retail / Grocery Stores / Malls

- Automotive / Aviation Facilities